What grease should I use in the JBA UCAs?

We recommend MOLY EP LITHIUM GREASE

What grease should I use in my JBA Upper Control Arms?

Mobilgrease XHP™ 222 Special grease is an extended-service lithium complex grease intended for a wide variety of applications and severe operating conditions. These greases were designed to outperform conventional products by applying cutting-edge, proprietary, lithium complex manufacturing technology. It is formulated to provide excellent high-temperature performance with superb adhesion, structural stability, and resistance to water contamination. This grease has a high level of chemical stability and offers excellent protection against rust and corrosion. This grease features high dropping points and a maximum recommended operating temperature of 140º C (284°F). Mobilgrease XHP 222 Special grease is available in NLGI grades 2 or 3 with an ISO VG 220 base oil viscosity.

Mobilgrease XHP 222 Special grease is designed for various applications, including the industrial, automotive, construction, and marine sectors. Their performance features make them ideal choices for operating conditions, including high temperature, water contamination, shock loading, and extended re-lubrication operations. Mobilgrease XHP 222 Special is an extreme pressure grease fortified with 0.75% molybdenum disulfide that provides protection from wear under conditions pivoting and other conditions that lead to loss of oil film.

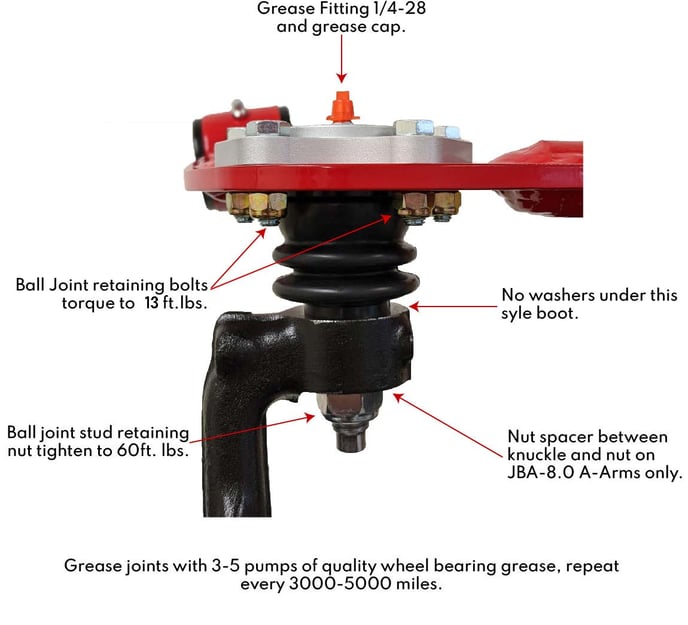

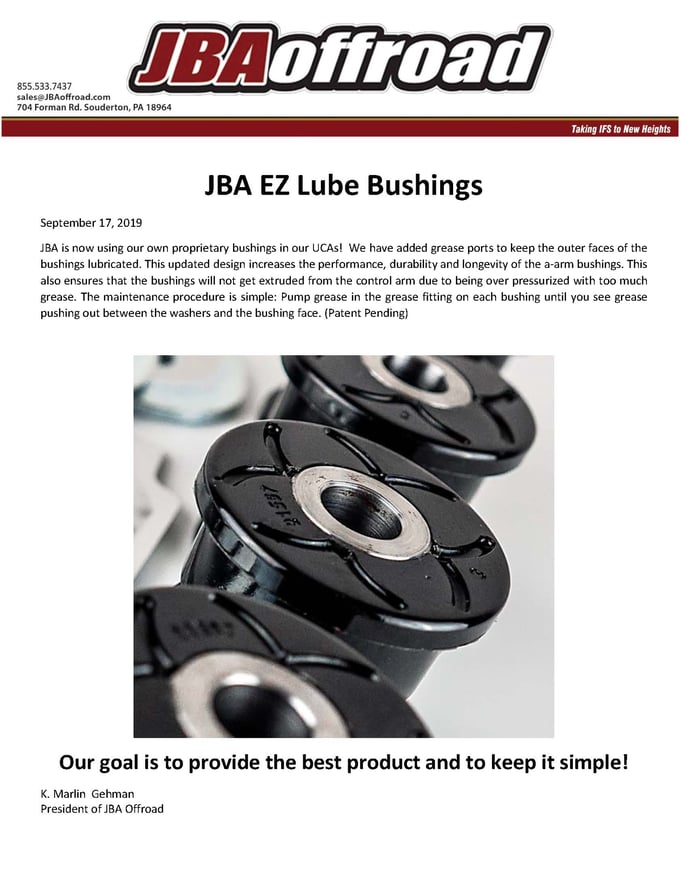

We recommend using a high-quality grease gun and adding 3-4 pumps of grease to the ball joint, until the dust boot starts to swell and pump grease into the bushings until you see grease consistently pushing out from the bushings' EZ Lube ports. Repeat every every 3,000 to 5,000 miles. If you drive through creeks and mud pits, we recommend greasing the ball joint after you are done playing in the mud and water.

As of October 2019, we used these bushings in our first production run. JBA EZ lube bushings can handle more than 1 pump of grease at 3,000—to 5,000-mile service intervals.

Several manufacturers have lithium moly greases with roughly similar compositions and properties. These manufacturers include Chevron EP Moly, Valvoline Multi-Vehicle Moly Fortified, Pennzoil EP with Moly, Tractor Supply Traveler Extreme Duty 3% Moly, John Deere HD Moly, Motomaster Moly Extreme Pressure, Mystik High Temp 3% Moly #2, Kubota Moly-Lithium, Lucas Heavy Duty Mining and Construction, Shell Rotella SD moly, Phillips 66 Megaplex XD5, Fuchs Renolit FLM 2 lithium moly, LiquiMoly LM 47 Long-Life Grease + MoS2, DuPont Molykote BR-2 Plus.

Do not use!

Lucas Red n’ Tacky does not work or play well with our bushings. It makes them squeak quickly and eventually damages them. We`ve had similar issues with other red greases and some synthetics.

![JBAoffroad 950 x 250.png]](https://support.jbaoffroad.com/hs-fs/hubfs/JBAoffroad%20950%20x%20250.png?height=50&name=JBAoffroad%20950%20x%20250.png)